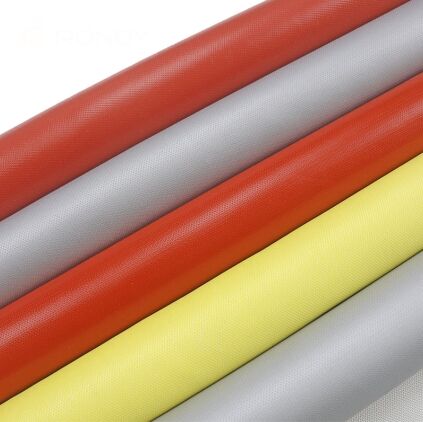

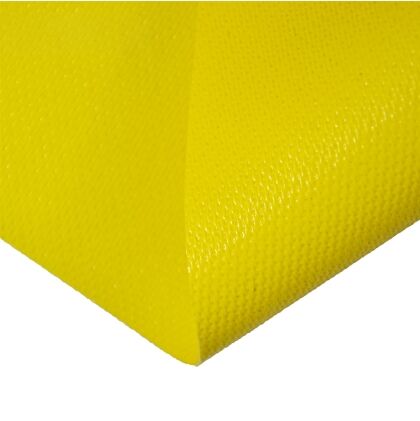

As a renowned silicone - coated fiberglass fabric manufacturer, Shandong Rondy Composite Materials Co., Ltd. has established itself as a leader in the industry through its commitment to quality, innovation, and customer satisfaction. Our manufacturing process begins with the selection of the finest raw materials. We source high - purity fiberglass yarns that are known for their strength, durability, and heat - resistant properties. These yarns are then carefully inspected to ensure they meet our strict quality standards before being used in the weaving process. The weaving of the fiberglass fabric is carried out using state - of - the - art looms. Our skilled technicians monitor the weaving process closely to ensure that the fabric has a uniform structure, high tensile strength, and excellent dimensional stability. This precise weaving is crucial as it forms the base for the subsequent silicone coating. The silicone coating is applied using advanced coating technology. We use high - quality silicone resins that are specially formulated to provide optimal heat - resistance, chemical resistance, and flexibility. The coating process is carefully controlled to ensure an even distribution of the silicone on the fiberglass fabric, resulting in a smooth and consistent surface. As a silicone - coated fiberglass fabric manufacturer, we understand the importance of customization. Different industries and applications have unique requirements, and we offer a wide range of customization options. Customers can choose from various sizes, thicknesses, and colors of the fabric. We can also customize the fabric with additional features such as reinforced edges, grommets, or special coatings to meet specific application needs. Quality control is an integral part of our manufacturing process. We have a comprehensive quality management system in place that adheres to international standards such as ISO9001 and ISO14004. Our products are tested at every stage of production to ensure they meet or exceed industry standards for heat - resistance, strength, and durability. We also comply with regulations such as CE, UL94, and REACH to ensure the safety and environmental friendliness of our products. With our extensive experience and expertise, we have built a strong reputation in the global market. We export our silicone - coated fiberglass fabric to over 25 countries, serving a diverse range of industries including aerospace, automotive, electrical, and construction. Our commitment to the "customer first, service anytime, anywhere" principle ensures that we provide excellent customer support, from pre - sales consultation to after - sales service.

Copyright © 2025 by Shandong Rondy Composite Materials Co., Ltd. — Privacy Policy