Key Properties of Silicone Coated Fiberglass Fabric

Composition and Structural Integrity

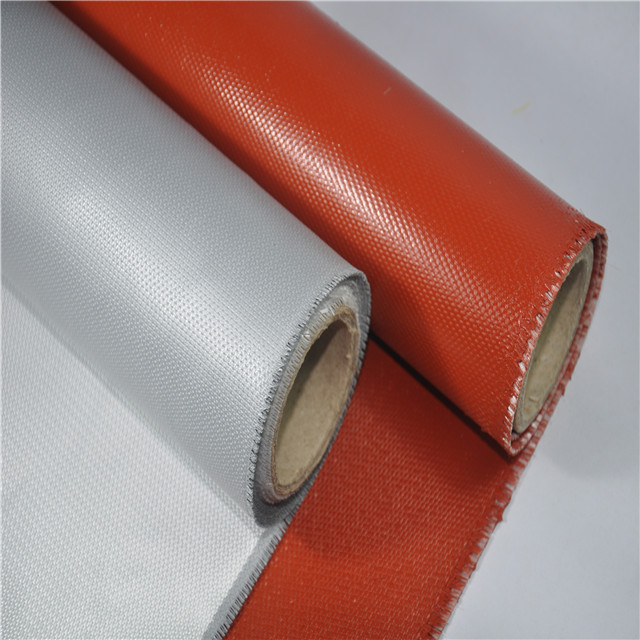

Silicone coated fiberglass fabric combines high strength fibers with a protective silicone layer, making it tough enough for serious industrial work. The silicone coating acts like armor against tears and frays, holding up under all sorts of stress conditions. What makes this material stand out is how it manages to stay lightweight while still packing serious tensile strength, so workers can handle it without struggling but still get reliable performance from day one. Manufacturers love this stuff for things like equipment covers and thermal insulation because it lasts way longer than standard options. Beyond just looking good on spec sheets, the silicone actually makes these fiberglass rolls perform better in real world situations where durability matters most.

Thermal Resistance and Temperature Range

Silicone coatings on fiberglass fabric give it impressive heat resistance, so it can handle temperatures anywhere between -50 degrees Fahrenheit all the way up to 500 degrees. Because of this feature, many different industrial settings find it useful, especially places where extreme heat is common. When working near hot surfaces or during welding operations, this material stays intact without transferring excessive heat, making workplace safety much better. Testing organizations like ASTM have run various experiments showing how well the fabric holds together under intense heat conditions. For companies needing materials that stand up to high temperatures, silicone coated fiberglass rolls are becoming essential parts of their operations across multiple sectors.

Chemical and Moisture Resistance

Fiberglass fabric treated with silicone shows remarkable resistance to chemicals because of how silicone naturally works. The material holds up well against all sorts of chemicals, oils, and solvents without breaking down over time. Moisture doesn't affect it much either, which helps keep the fabric strong even when exposed to damp conditions. We've seen this stuff last longer than regular untreated fabrics in places where there's lots of corrosion going on. That's why so many different industries rely on silicone coated fiberglass for jobs where they need something that won't get damaged by harsh chemicals or water exposure. From chemical plants to food processing facilities, this type of fabric keeps performing reliably year after year.

Advantages Over Traditional Materials

Durability in Extreme Environments

Silicone coated fiberglass fabric stands out for how tough it really is, way tougher than regular stuff like cotton or those basic synthetics we see everywhere. What makes this material so special is how it holds up against pretty much anything thrown at it. It doesn't mind getting baked under UV light, soaked through with moisture, or exposed to extreme heat. That kind of toughness explains why welders and folks working in hot industrial settings rely on these materials so much. Industry data shows something interesting too. These silicone coated fabrics tend to last way longer than their uncoated counterparts, sometimes doubling or even tripling the service life. For anyone looking at long term value, this matters a lot. The fact that they keep performing reliably even after years of rough treatment makes them ideal choices for those critical fiberglass welding blanket applications where failure just isn't an option.

Safety Benefits: Flame Retardancy and Electrical Insulation

Silicone coated fiberglass has excellent flame resistance which makes it really important for safety in industrial workplaces. When fires break out, these materials can help prevent them from spreading quickly, so they're essential in factories and other places where worker safety matters most. Another benefit worth mentioning is how well these fabrics insulate against electricity. This means workers can handle equipment without worrying about shocks or short circuits happening nearby. Most safety standards organizations have approved silicone coated fiberglass for protective gear because of just how safe it proves to be in real world conditions. Manufacturers across various industries continue to rely on this material precisely because it combines multiple safety benefits in one package.

Reduced Maintenance and Longevity

Silicone coatings cut down on maintenance because they don't stain easily and wipe clean with minimal effort. For manufacturers looking to save time and money, this means silicone coated fiberglass fabric becomes a smart pick across various industrial settings. When it comes to lasting power, these materials stand up well against regular wear and tear from friction and abrasion, making them last longer than many alternatives. Some real world testing shows maintenance costs drop by around 30% compared to traditional options, meaning companies often recover their upfront costs within just a few months of installation. That's why so many facilities that need reliable performance day after day end up choosing these durable, low maintenance fabrics despite the higher price tag at purchase.

Industrial and Commercial Applications

Welding Blankets and Spark Protection

Welding blankets made from silicone coated fiberglass are everywhere on job sites because they stop sparks and molten metal bits that could start dangerous fires. What makes this material stand out? It holds back those flying hot particles while standing up to intense heat without breaking down. No wonder welders keep coming back to it time after time. Recent market reports show growing interest in protective gear for welding work, and products with silicone coatings take up quite a chunk of sales since workers trust them to do the job right. Industries where safety matters most, like shipbuilding or automotive repair shops, really value how these materials handle harsh conditions day after day. They get solid protection without having to sacrifice quality or deal with constant replacements.

Thermal Insulation for Pipes and Equipment

Silicone coated fiberglass works really well as thermal insulation to stop heat escaping from pipes and industrial equipment, which helps save energy in the long run. What makes this material stand out is how it can handle extreme temperatures while also preventing condensation buildup that damages what's underneath. Many factories have seen real benefits after switching to this type of insulation. Take food processing plants for instance they often report cutting down on heating costs significantly once installed. When thermal losses drop, whole industrial operations run smoother and cheaper. For businesses looking to cut expenses without sacrificing performance, investing in silicone coated fiberglass insulation just makes good business sense.

Fire Curtains and Safety Barriers

Silicone coated fiberglass fire curtains act as both flexible and strong defenses against spreading fires, making them great additions to commercial buildings looking to boost safety measures. These curtains are light enough to handle during installation but still hold up under extreme conditions, which explains why they work so well across different types of spaces where fire prevention matters most. Recent data shows that many businesses across manufacturing and retail sectors have started adopting these fire barriers simply to stay compliant with updated building codes. What makes these products stand out is how they protect without compromising on structural strength, helping facilities maintain their safety ratings even after installation. Industrial plants in particular find value in installing these curtains at critical points throughout their operations, knowing this extra layer of protection helps keep valuable equipment safe and workers protected during emergencies.

Innovations in Silicone Coating Technology

Eco-Friendly and Sustainable Coatings

Recent improvements in silicone coating tech have brought about a new era for environmentally friendly and sustainable coatings that cut down on environmental damage without sacrificing how well products work. What makes these innovations special? They rely heavily on renewable materials, something that fits right into what many industries are doing now to become greener overall. According to recent market studies from the Market Research Institute, companies across various sectors are increasingly adopting these kinds of coatings. Why? Well, customers want them and regulations are getting stricter too. For businesses operating today, sustainability isn't just nice to have anymore it's becoming necessary. Companies need to balance good performance with lower emissions if they want to stay competitive in this changing landscape.

Smart Textiles with Integrated Sensors

Putting sensors into silicone coated fabrics is changing how we think about smart textiles, basically creating materials that react to what's going on around them. The idea is pretty simple really these fabrics can track things like temperature changes, pressure points, even detect moisture levels which gives manufacturers all sorts of useful information across different industries. Industry insiders mention there's been quite a rush lately with companies filing numerous patents in this area, showing just how big the market might get. What makes this technology stand out though is its ability to provide instant feedback when needed most. Think about workers wearing protective gear that alerts them to dangerous conditions before they become serious issues. That kind of real time data gathering could transform everything from safety equipment to medical wearables in the coming years.

Enhanced Flexibility for Complex Shapes

The latest advances in material science have really transformed how silicone coated fiberglass bends and flexes, making it possible to wrap around complicated shapes while still holding up structurally. We're seeing this newfound flexibility create all sorts of opportunities in different fields, especially in car manufacturing and aircraft design where space constraints can be brutal. Industry insiders report that companies are asking for more of these versatile materials because they let designers create better performing products. When parts fit together more naturally thanks to their ability to conform to odd angles, assembly becomes faster and cheaper. Plus, products tend to last longer since the materials don't crack or break under stress like traditional options sometimes do. This makes sense when looking at everything from airplane interiors to luxury car components.

Choosing the Right Fiberglass Fabric Roll

Weight and Thickness Considerations

Knowing the weight and thickness of fiberglass fabric matters a lot when it comes to getting good results from whatever project we're working on. Thicker materials tend to last longer but they also add extra weight to whatever we're building. Thin fabrics bend easier which makes them great for certain jobs, though they won't protect against damage as well. When picking out fabric specs, take a close look at what exactly needs to be done. Boat builders might need something different than someone making electrical enclosures. Most manufacturers actually have charts showing recommended weights for various uses. These recommendations aren't just random numbers either they come from years of trial and error figuring out what works best in real world conditions.

Comparing Fire Blanket Price vs. Performance

When looking at what fire blankets cost versus how well they actually work, businesses need to think beyond just numbers on a spreadsheet. Spending extra money upfront for better quality materials often pays off in the long run because these blankets last longer and offer safer protection during emergencies. Recent trends indicate that companies are starting to prioritize effectiveness over cheap prices when buying fire safety equipment. After all, nobody wants to save a few bucks only to find out later that their fire blanket failed when needed most. The smarter choice focuses on getting reliable gear that stands up to real world conditions, which makes sense both from a safety standpoint and financially speaking over time.

Sourcing Chopped Fiberglass Strands for Custom Solutions

Getting good quality chopped fiberglass strands matters a lot when making custom products that fit particular requirements. Knowing how these materials get made and where they come from makes all the difference in whether the final item will pass safety checks and perform properly. When looking at potential suppliers, it pays to spend time checking out who actually delivers consistent results. A reliable vendor means better quality control throughout production, which translates to materials that actually work as intended for whatever application they're needed for. The whole point is getting something that not only meets specs but also stands up under real world conditions without falling apart prematurely.