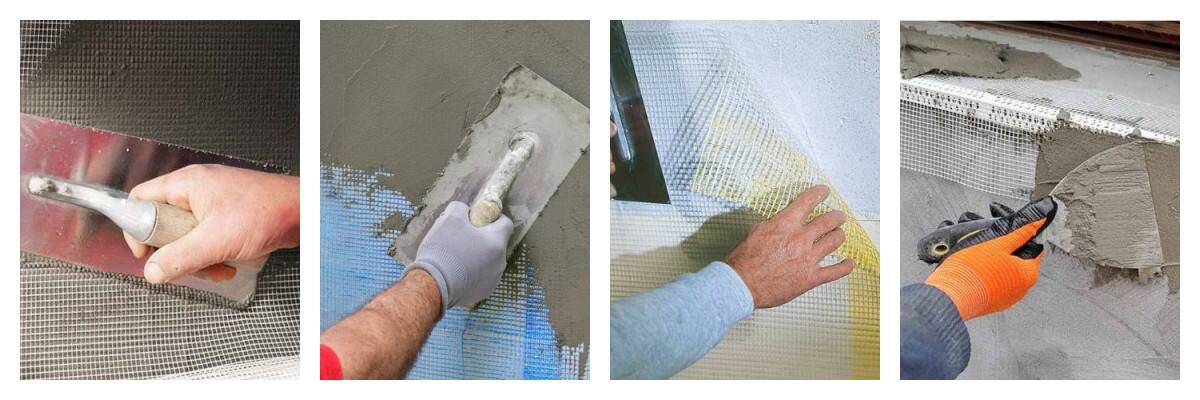

Reliable and economical general-purpose building reinforcement solutions provide precisely matched crack resistance protection for wall plastering, tile backing, and foundation reinforcement

Fiberglass Mesh is engineered for daily construction and renovation projects. Manufactured from fiberglass yarn with a protective alkali-resistant coating, it integrates seamlessly into cementitious bases to provide reliable tensile strength and crack resistance.

Alkali resistance: Utilizes an alkali-resistant coating, effectively resisting corrosion from cement mortar environments.

Construction-friendly: Flexible, easy to cut, and conforms well to the body.

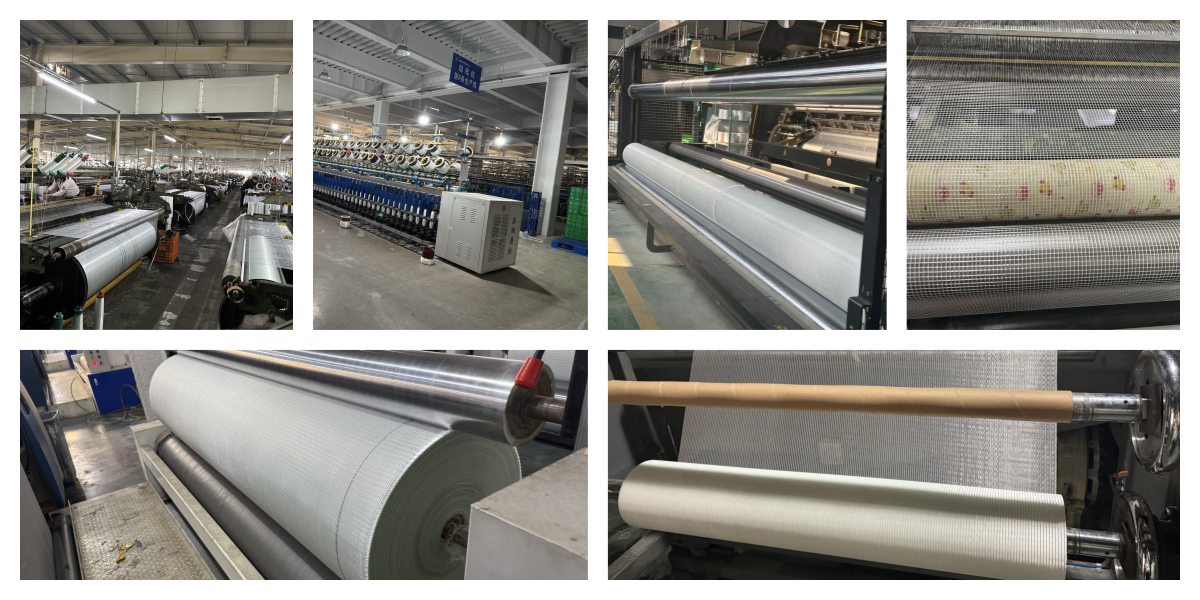

Stable quality: Produced on a standardized production line, ensuring controllable quality.

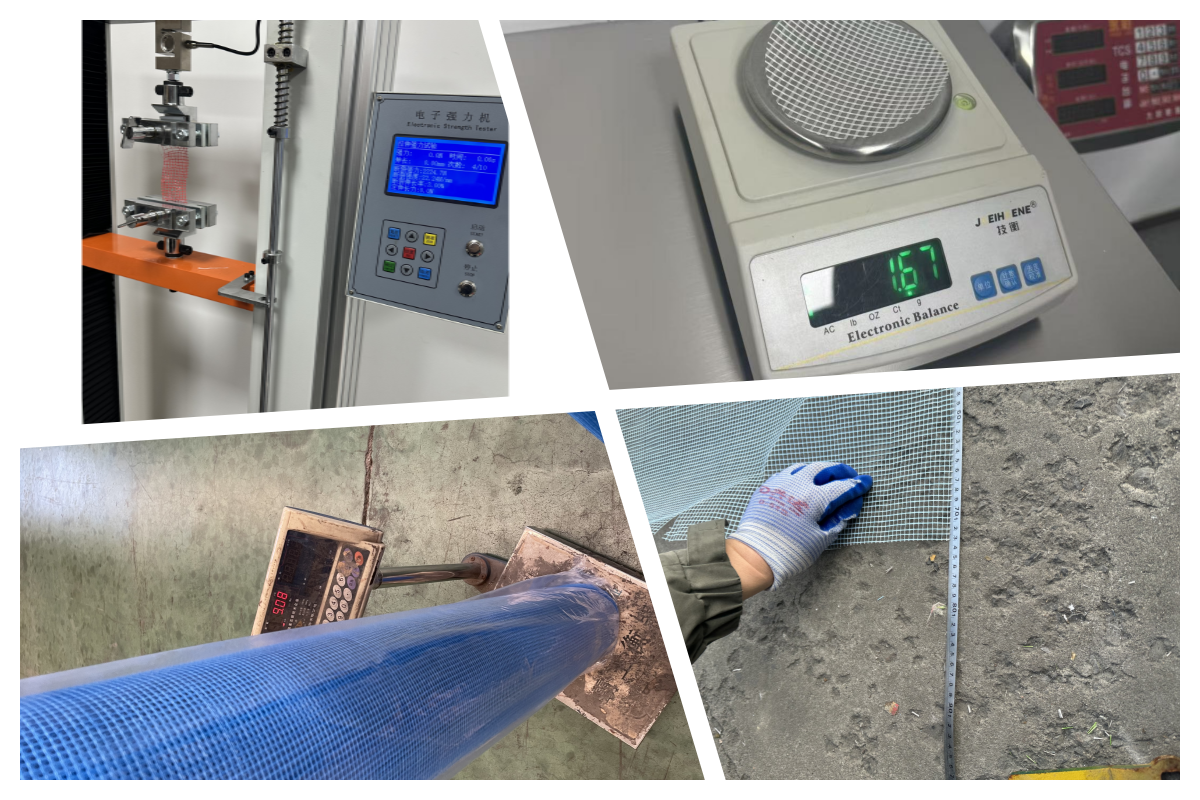

|

Specification |

110g/m2 |

125g/m2 |

130g/m2 |

|

Tensile Strength |

>=1200N/50mm |

>=1500N/50mm |

>=1800N/50mm |

|

Alkali resistance retention rate |

>=50% |

>=50% |

>=50% |

|

Mesh Size |

4x4mm/5x5mm |

4x4mm/5x5mm |

4x4mm/5x5mm |

|

Color |

White, yellow,green,blue,etc |

||

|

Size |

Standard 1mx50m, max length 800 meter one roll, Width:10cm,12cm,14.28cm,15cm,16cm, 20cm,25cm, 30cm,100cm, max 200cm |

||

|

Application |

Drywall joints ,wall plaster reinforcement , tile backing |

||

|

Packing |

Individually rolled in PP bag, outer packing: carton, woven bag , pallet |

||

· For Interior Plastering (Full Wall): Use 125g/m2 or 130g/m2 fiberglas mesh embedded in the base coat plaster for comprehensive crack prevention.

· For Tile Backing (Walls & Floors): Use 125g/m2 or 130g/m2 fiberglass mesh as a stabilizing layer under tile adhesive to prevent substrate cracks from telegraphing.

· For Drywall Joints & Repairs: 110g/m2 fiberglass mesh tape (self-adhesive available) is the perfect, economical solution for taping and finishing drywall seams.

· General Procedure: 1) Prepare clean, stable substrate. 2) Apply base coat mortar/plaster. 3) Embed the mesh firmly, ensuring full embedment and overlap (≥10cm). 4) Apply the final coat.

Q:Why Source From Us?

· Direct Factory Supplier: Competitive pricing with full quality control.

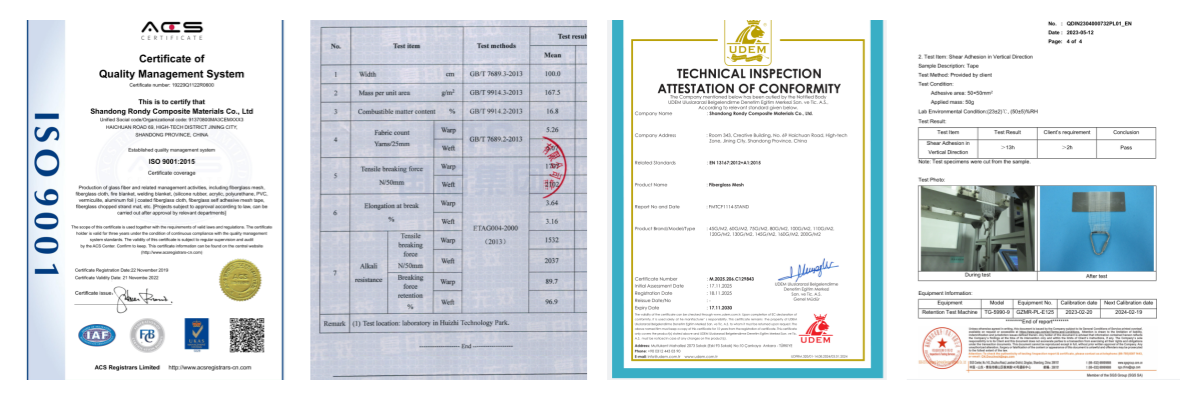

· Certified Quality: Our production is compliant with international standards (CE, ISO 9001 available).

· Expert Support: Get technical guidance to select the right product for your specific project.

· Flexible Logistics: Reliable global shipping with FOB, CIF, or EXW terms.

Q: Which weight is right for my project?

A: It depends on the substrate and stress. 110g for light-duty, 125g for general interior walls/medium tiles, 130g for high-stress areas/large tiles. Our team can advise you based on your project details.

Q: Can you produce custom sizes or weights?

A: Yes. We regularly produce custom widths (from 60cm to 1.5m) and can adjust grammage. Contact us with your requirements.

Q: Do you provide samples?

A: Yes. Sample rolls of any standard grade are available for evaluation.

Consistency You can Build Upon

Our fully automated production line and over three quality inspections ensure that each roll of mesh fabric has uniform weight, strength, and coating, preventing unexpected performance fluctuations for your construction team and guaranteeing consistent final project quality.

Export Support for your specific Project

We offer free samples and one-on-one technical consultation.

Supply security& Flexibility

We maintain a large inventory of raw materials and standard products, supporting everything from small-batch trial orders to full-container mixed shipments. Custom widths, lengths, packaging, and various trade terms are available.

Why Global Builder Trust Rondy

We hold CE, ISO9001, and SGS certifications and have provided a stable supply to 50 distributors and construction projects worldwide since 2016.

Copyright © 2025 by Shandong Rondy Composite Materials Co., Ltd. — Privacy Policy