Understanding Fiberglass Mesh and Its Construction Applications

What is fiberglass mesh and why it matters in building projects?

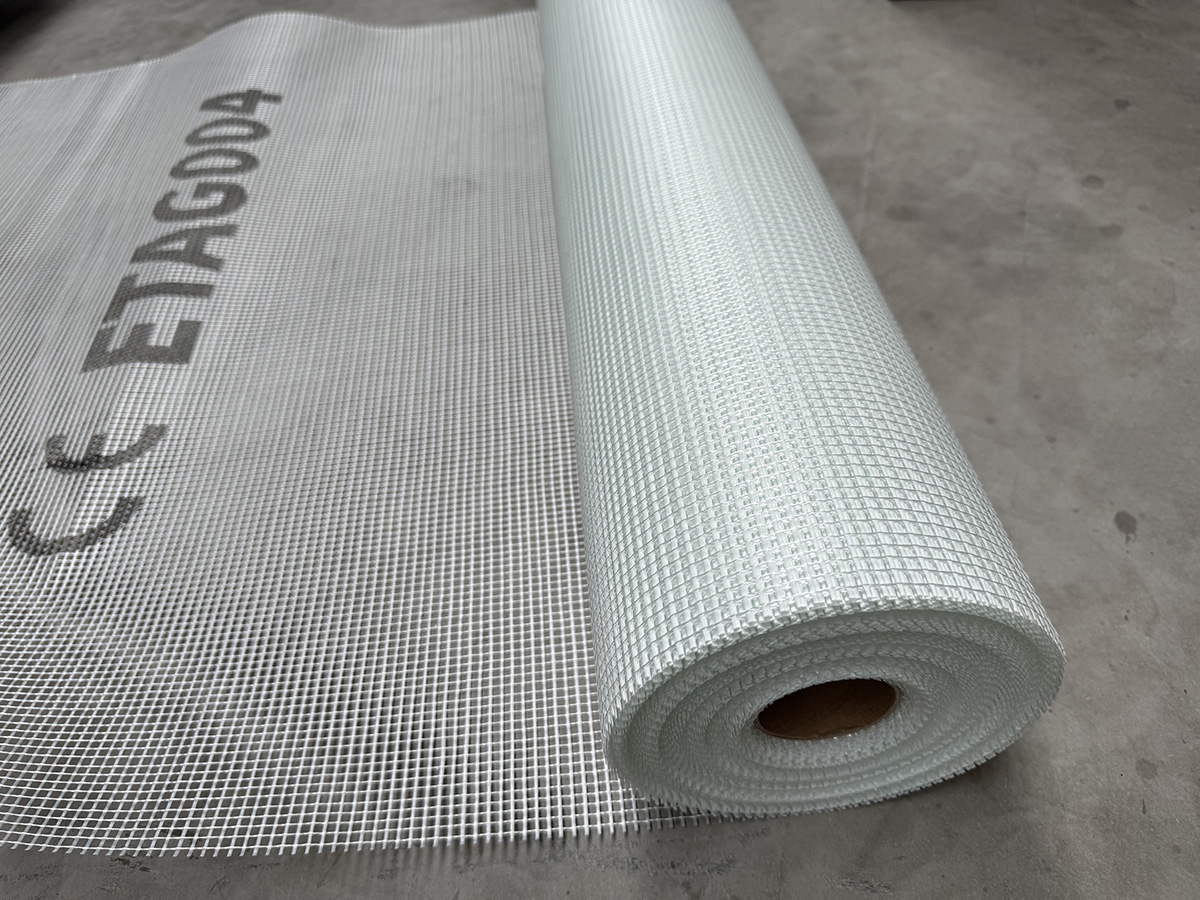

Fiberglass mesh comes in a flexible grid form created when manufacturers weave together thin glass strands and then apply an alkali resistant polymer coating, usually something like acrylic or PVC. What makes this coating so important? Well, it protects those delicate glass fibers from getting damaged by moisture, harsh chemical conditions found in concrete mixtures, and all sorts of weather over time. Builders really appreciate this stuff because it combines amazing tensile strength with being surprisingly light weight while still standing up against corrosion issues. And here's another big plus compared to traditional steel options: no rusting problems at all plus zero electrical conductivity. That makes fiberglass mesh particularly good for buildings where safety standards matter most and materials need to last decades rather than just years before replacement becomes necessary.

Common uses of fiberglass mesh in construction

Fiberglass mesh has become pretty common throughout the construction industry for reinforcing materials and keeping things stable. When working with drywall or plaster, this mesh stops those annoying cracks from forming at wall joints and around windows or doors. It actually works better than old fashioned paper tape because it's more flexible and sticks better too. For exterior walls, especially in EIFS systems and stucco applications, fiberglass mesh makes a big difference. Contractors love how it boosts impact resistance while controlling those pesky hairline cracks that tend to appear over time. On roofs and foundation walls, the mesh adds strength to waterproofing layers without losing flexibility needed for temperature changes. Tile installers often use it as an underlayment material, and many builders incorporate it into concrete slabs and masonry work to reduce cracking caused by stress points in the structure.

The growing role of fiberglass mesh in structural integrity

Fiberglass mesh plays a big role these days in making buildings stronger and longer lasting. Research indicates walls with good installation of this mesh can resist cracks about 60 percent better than those without. Unlike metal alternatives, fiberglass won't rust or corrode even when exposed to extreme weather conditions or chemical exposure. What makes this material stand out is how it bends rather than breaks when stressed. This flexibility lets it handle things like foundation settling or temperature changes without breaking apart. With current building regulations pushing for greener materials and structures that last longer between repairs, many contractors now specify fiberglass mesh as part of their construction plans. Buildings incorporating this material tend to require fewer fixes over time and generally hold up much better against whatever Mother Nature throws at them.

Key Selection Criteria for Fiberglass Mesh Based on Performance

Fiber type, weave, and coating: Core selection factors

When choosing fiberglass mesh, there are several factors worth considering first. Fiber composition matters a lot, along with how it's woven together and what kind of coating has been applied. For work involving concrete or other cement based materials, alkali resistant glass fibers become absolutely necessary. Without them, the material would break down chemically over time. The tightness of the weave plays a big role too. Most people measure this in threads per inch or sometimes centimeters. Generally speaking, tighter weaves tend to hold up better under stress and bridge cracks more effectively. Then there's the polymer coating which helps the mesh stick properly to whatever surface it's being applied to while also making it more resistant to water damage. All these characteristics combined decide whether a particular mesh works well for certain weight requirements, weather conditions, and installation techniques on construction sites.

Alkali resistance, mesh size, and waterproofing suitability

Resistance to alkalis matters a lot when working with concrete and stucco since those materials have naturally high pH levels that can break down regular glass fibers pretty quickly. The mesh size something contractors often overlook refers to how many holes there are in each square inch of material. This actually impacts two things at once support throughout the surface and how well adhesives can get into the mix. Smaller meshes give better reinforcement across the board, but they also mean needing more base coat material during application. When it comes to keeping water out, nothing beats a really tight weave combined with a polymer coating. Such meshes stop moisture from getting through while still letting vapors escape naturally. This balance prevents water buildup underneath which could otherwise lead to peeling or separation issues down the road.

Tensile strength, elongation, and weather resistance

The tensile strength of construction grade meshes generally falls between 50 and 100 kN per meter, which basically tells us how well the material holds up under stress. When we talk about elongation rates around 3 to 5 percent, this means the mesh can actually stretch quite a bit before snapping apart something important for buildings that need to move with environmental changes rather than crack or fail completely. Weather resistance matters too looking at things like UV protection so materials don't degrade in sunlight, working properly even when temps swing wildly from below freezing at -40 degrees Celsius all the way up to scorching 80 degrees, plus staying strong despite exposure to water and damp conditions. Project requirements really dictate what works best here. Buildings in earthquake prone areas tend to perform better with meshes that have higher elongation characteristics, whereas structures facing constant wind pressure absolutely need stronger tensile properties to stand up against those forces over time.

Balancing cost vs. long-term performance in fiberglass mesh selection

Cost matters at first glance, but what really counts is how well something performs over time. Cheap meshes often skip important treatments against alkali damage and UV degradation, which means they tend to crack or warp sooner than expected, leading to expensive fixes down the road. Real world testing shows good quality fiberglass mesh can make surfaces last anywhere from 40 to 60 percent longer than those without reinforcement. Most professionals recommend matching mesh grades to where they'll be used. Put the top shelf stuff in spots that get constant stress or sun exposure, save the regular grade for places that aren't as demanding. This strategy keeps things durable without breaking the bank throughout the entire lifespan of the building.

Types of Fiberglass Mesh and Their Project-Specific Applications

Fiberglass mesh comes in different weights and coatings depending on what the job requires. There are basically two types out there standard weight mesh and the heavier stuff. Standard weight usually ranges from around 90 to 145 grams per square meter. This type works well for most common applications like reinforcing drywall, plaster work, and stucco finishes. Then we have the heavy duty version which starts at about 165 grams per square meter and goes higher. The heavier mesh offers much better strength against tension forces and can withstand impacts better too. That makes it the go to choice for bigger projects such as commercial buildings, foundation walls, and areas where earthquakes might be a concern.

Standard weight vs. heavyweight fiberglass mesh: Differences and uses

Standard weight mesh strikes a good balance between being flexible enough to work with but still strong enough for most jobs around homes and smaller commercial buildings. Contractors often reach for this type when working on exterior insulation finish systems (EIFS), fixing those pesky cracks between drywall panels inside walls, or anywhere they need to prevent future cracking issues. On the other hand, heavyweight mesh gets put into much tougher situations where things are going to get rough. Think about concrete pours, rooftop edges called parapets, or any spot that might face harsh weather conditions or accidental bumps from equipment. These heavier meshes just hold up better over time in these demanding spots.

Corner mesh for enhanced edge durability in drywall and plaster

Corner mesh that comes pre-formed works great for reinforcing those tricky spots where walls meet in drywall or plaster jobs. The creases are already built into it so installers get pretty much the same thickness every time, and everything lines up properly. Made from fiberglass too, which means those weak spots around the edges don't crack as easily when pressure builds up. Contractors love this stuff because it cuts down on installation headaches, and buildings end up with corners that last much longer whether they're fixing up a home or working on some big commercial project somewhere.

Fiberglass mesh in exterior insulation and finish systems (EIFS)

In EIFS, fiberglass mesh is embedded in the base coat to distribute stress and prevent surface cracking. Industry standards recommend alkali-resistant mesh weighing 145–165g/m² for optimal performance. Proper selection and installation are essential to maintain the system's weather resistance, energy efficiency, and long-term integrity.

Roofing and waterproofing: Role of fiberglass mesh in bitumen membranes

Adding fiberglass mesh to bituminous waterproofing membranes and roofing systems makes them stronger against tearing and wear over time. The mesh spreads out stress caused by temperature changes and keeps the material intact when people walk on it or when exposed to sunlight for extended periods. For roofs that need extra strength, contractors often go with heavier mesh options weighing around 250 grams per square meter or even more. These heavier versions stand up better to harsh weather and heavy usage, making them ideal for commercial buildings and industrial applications where reliability is absolutely critical.

Interior applications: Drywall joints, tile underlayment, and crack prevention

When working on interior projects around the house, many contractors reach for self adhesive fiberglass mesh tape. These tapes help strengthen those tricky drywall seams where cracks tend to form, they also stop plaster from cracking and keep tiles firmly in place beneath their surface. The main reason builders like these mesh tapes instead of old fashioned paper ones? Well, they bend easily around corners and stick right onto the wall without needing extra tools or messy glue. For anyone laying down tiles, this mesh does wonders by holding everything steady underneath. What happens when there's no mesh? The base material shifts slightly as people walk across it day after day, which eventually leads to hairline fractures appearing in both the thin set mortar and the actual tiles themselves months later.

Matching Fiberglass Mesh to Project Type: Residential vs. Commercial

Residential vs. commercial needs: Load, code, and durability requirements

For homes, builders usually go with standard weight fiberglass mesh around 145 to 165 grams per square meter. This helps prevent cracks and gives decent durability for stucco and plaster work on residential properties. But when it comes to commercial buildings, things get different. These structures need much heavier mesh at least 250 grams per square meter or more because they have to support greater structural loads, comply with tougher building regulations, and stand up better against impacts. The reality is commercial applications face about two to three times as much stress compared to what residential buildings experience. That's why stronger, more durable reinforcement materials become absolutely essential for these types of construction projects.

Cement and concrete reinforcement in large-scale commercial builds

Fiberglass mesh plays an important role as reinforcement material in various commercial construction projects including floor slabs, parking structures, and foundation work. What makes this material stand out is its impressive tensile strength ranging from around 50 to 100 kilonewtons per meter, plus it doesn't react badly with alkalis unlike traditional steel options. For big concrete jobs where rust might become a problem over time, many builders choose fiberglass instead. When dealing with harsh chemicals common in industrial settings, contractors frequently go for the epoxy coated version since it lasts much longer under these conditions. The extra protection really pays off in terms of maintenance costs down the road.

Optimizing fiberglass mesh for cost, compliance, and lifespan

Choosing the right mesh involves finding that sweet spot between what it costs upfront and how well it performs down the road. For homes, going with medium weight mesh usually works best from a budget standpoint. Commercial buildings can afford to spend more on better quality materials since they last longer and need less fixing up over time. Following building codes is essential for safety reasons, especially for bigger projects. Many commercial applications actually need outside verification and testing before approval. This adds around 15 to 25 percent to the total price tag, but most contractors agree it's worth the extra money when considering that these installations typically stand up to tough environments for more than two decades without major issues.

FAQ

What is the primary purpose of fiberglass mesh in construction?

The primary purpose of fiberglass mesh in construction is to reinforce materials, increase tensile strength, and prevent cracking, particularly in drywall, plaster, exterior walls, and concrete slabs.

Is fiberglass mesh resistant to alkalis found in concrete and stucco?

Yes, high-quality fiberglass mesh is often treated with alkaline-resistant coating, making it suitable for use with concrete and stucco, which possess naturally high pH levels.

What types of fiberglass mesh are available for construction purposes?

Fiberglass mesh comes in standard weight (90-145 grams per square meter) for common applications like drywall and stucco, and heavyweight options (165 grams per square meter or more) for demanding projects involving concrete and roofing applications.

How does fiberglass mesh improve the lifespan of construction materials?

By reinforcing structural elements and preventing cracks, fiberglass mesh adds to the longevity of construction materials, potentially increasing their lifespan by 40 to 60 percent compared to unreinforced materials.

Why is fiberglass mesh preferred over steel in some constructions?

Fiberglass mesh is lightweight, resistant to corrosion and alkalis, and has zero electrical conductivity, making it a preferred choice in environments where these factors are critical.

Table of Contents

- Understanding Fiberglass Mesh and Its Construction Applications

- Key Selection Criteria for Fiberglass Mesh Based on Performance

-

Types of Fiberglass Mesh and Their Project-Specific Applications

- Standard weight vs. heavyweight fiberglass mesh: Differences and uses

- Corner mesh for enhanced edge durability in drywall and plaster

- Fiberglass mesh in exterior insulation and finish systems (EIFS)

- Roofing and waterproofing: Role of fiberglass mesh in bitumen membranes

- Interior applications: Drywall joints, tile underlayment, and crack prevention

- Matching Fiberglass Mesh to Project Type: Residential vs. Commercial

-

FAQ

- What is the primary purpose of fiberglass mesh in construction?

- Is fiberglass mesh resistant to alkalis found in concrete and stucco?

- What types of fiberglass mesh are available for construction purposes?

- How does fiberglass mesh improve the lifespan of construction materials?

- Why is fiberglass mesh preferred over steel in some constructions?