Reliable and economical general-purpose building reinforcement materials fiberglass mesh provide basic crack resistance protection for plastering, insulation and repair projects.

Fiberglass mesh with an alkali-resistant coating. It is designed to effectively reinforce cement and gypsum-based mortar layers, inhibiting and preventing the formation and propagation of surface cracks by dispersing stress. As a durable and proven solution on the market, its stable performance, excellent cost-effectiveness, and wide applicability have made it an ideal choice for construction projects.

Feature :

• Good Alkali Resistance: A specially treated coating effectively resists alkaline erosion from cement mortar, ensuring long-term reinforcement within the wall.

• Strength and Stability: Possesses excellent tensile strength in both warp and weft directions, evenly distributing internal stresses caused by drying shrinkage and temperature variations in the plaster layer.

• Construction-Friendly:Uniform mesh size, flexible and easily bent, easy to cut and apply, allowing for close adhesion to various curved surfaces and corners.

• Wide Compatibility:Suitable for most cement-based and gypsum-based adhesives, plaster mortars, and putties, making it a versatile interior and exterior wall reinforcement material.

• Economical and Practical: Achieves an optimal balance between performance and cost, providing a reliable option for budget-sensitive or standard-requirement projects.

Crack Prevention in Interior and Exterior Wall Plastering: Used as a joint strip for gypsum board or applied integrally to brick and concrete walls to prevent cracking of the plaster layer.

Base Layer for Thermal Insulation Systems (ETICS/EIFS): Used in high-requirement insulation systems as a reinforcing material for the plaster layer (Note: For ultra-high-rise buildings or extreme environments, our high-performance series is recommended).

Wall and Ceiling Repair: Used to repair cracks in existing walls or to provide a reinforcing layer for the renovation of old walls.

Tile Backing Substrate Treatment: Provides a smooth and strong substrate for tile installation on walls in wet areas.

User Guide

1. Surface Preparation: Ensure the substrate is firm, flat, clean, and free of dust or oil.

2. Mortar Application: Apply a sufficient amount of plastering mortar or adhesive to the substrate.

3. Laying the Mesh Fabric: Press the mesh fabric flat into the wet mortar, ensuring complete coverage without wrinkles.

4. Covering and Smoothing: Apply another layer of mortar over the mesh fabric, completely covering and smoothing to the desired thickness.

5. Key Note: Ensure at least a 10cm overlap between adjacent mesh fabric sections.

|

Product |

Finish Weight |

Yarn Tex |

Mesh Size |

Density |

Woven |

Tensile Strength |

||||

|

Code |

|

(Tex) |

mm |

(Counts/25mm) |

(N/5cm×20cm) |

|||||

|

|

|

Warp |

Weft |

Warp |

Weft |

Warp |

Weft |

|

Warp |

Weft |

|

RD100-5×5 |

100 |

67×2 |

200 |

5 |

5 |

5 |

5 |

leno |

≧750 |

≧1000 |

|

RD110-10×10 |

110 |

250×2 |

400 |

10 |

10 |

2.5 |

2.5 |

leno |

≧1250 |

≧1250 |

|

RD125-5×5 |

125 |

134×2 |

250 |

5 |

5 |

5 |

5 |

leno |

≧750 |

≧1000 |

|

RD130-5×5 |

130 |

134×2 |

300 |

5 |

5 |

5 |

5 |

leno |

≧1300 |

≧1400 |

|

RD145-4X4 |

145 |

134X2 |

300 |

4 |

4 |

6 |

6 |

leno |

≧1550 |

≧1650 |

|

RD145-5×5 |

145 |

134×2 |

350 |

5 |

5 |

5 |

5 |

leno |

≧1550 |

≧1700 |

|

RD160-4×4 |

160 |

134×2 |

300 |

4 |

4 |

6 |

6 |

leno |

≧1650 |

≧1600 |

|

RD160-5X5 |

160 |

134X2 |

400 |

5 |

5 |

6 |

6 |

leno |

≧1600 |

≧1850 |

|

RD165-4×5 |

165 |

134×2 |

350 |

4 |

5 |

6 |

5 |

leno |

≧1300 |

≧1300 |

|

RD300-4×5 |

300 |

200×2 |

700 |

4 |

5 |

6 |

5 |

leno |

≧2000 |

≧3000 |

Color: white ,green,yellow,orange,red ,etc

Width: 5cm -200cm, standard 100cm

North America :38inch , 48inch

Length : 10m-500m, standard 50m

North America :150ft

Note: The maximum roll length varies depending on the grammage. For larger roll sizes, please contact our professional sales.

Customized: print logo , self-adhesive, fire retardant

Package : Multiple packaging options are available.

Inner packing : plastic bag or shrink film

Outer packing : only shrink film, carton, woven bag ,big carton on

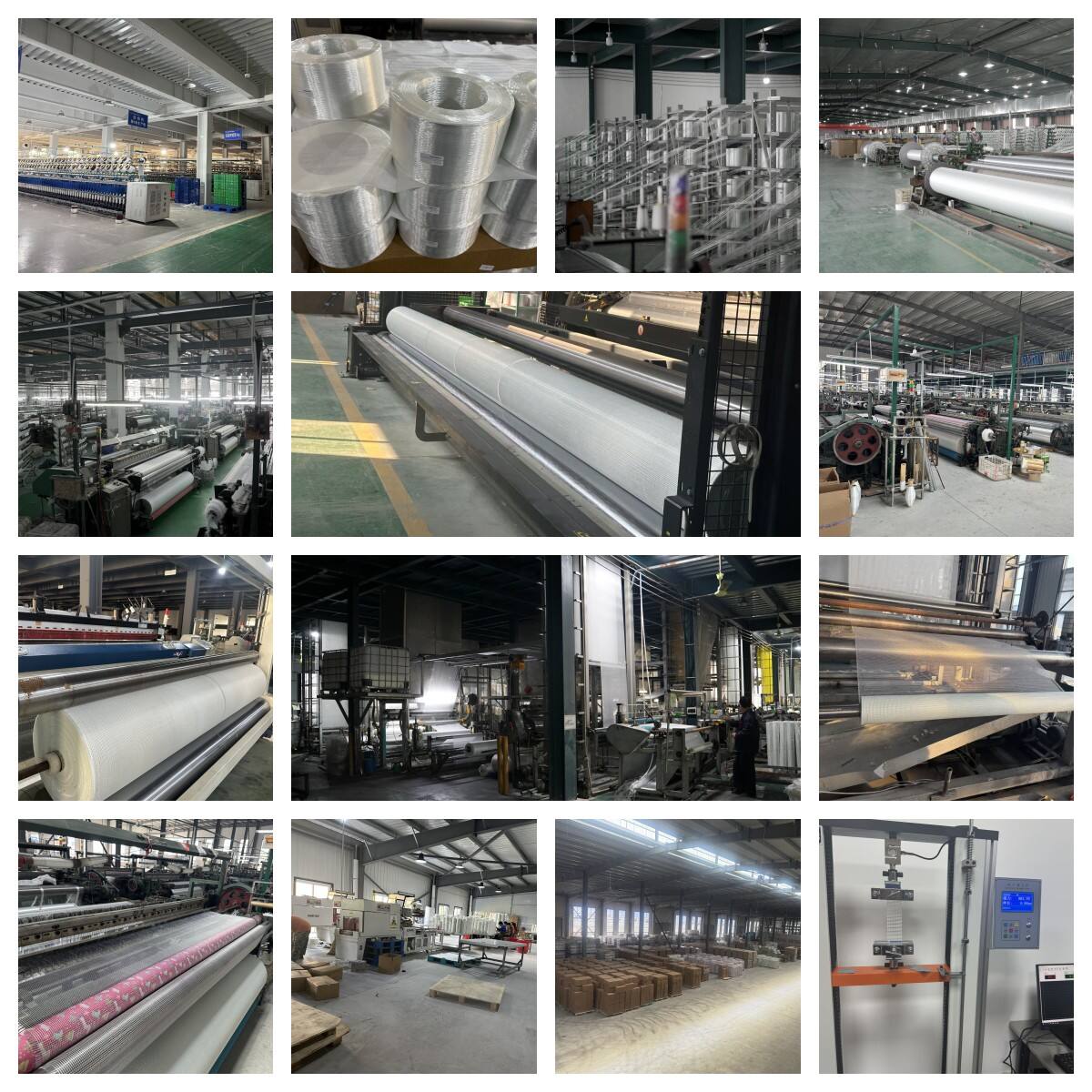

Four Steps of Precise Control, Focus on Quality

1. Strict Raw Material Selection: Using Grade A glass fiber yarn from brands like Taishan and Jushi, ensuring alkali resistance from the source.

2. Precision Weaving: High-precision looms ensure uniform mesh size and stable strength, meeting various specification requirements.

3. Core Coating: Exclusive formula coating, cured at a constant temperature, achieves permanent bonding with the fiber, ensuring ultra-long durability.

4. Full Inspection Before Leaving the Factory: Each roll undergoes online testing and laboratory testing to ensure qualified parameters and reliable performance.

We are committed to transforming complex craftsmanship into simple trust for you.

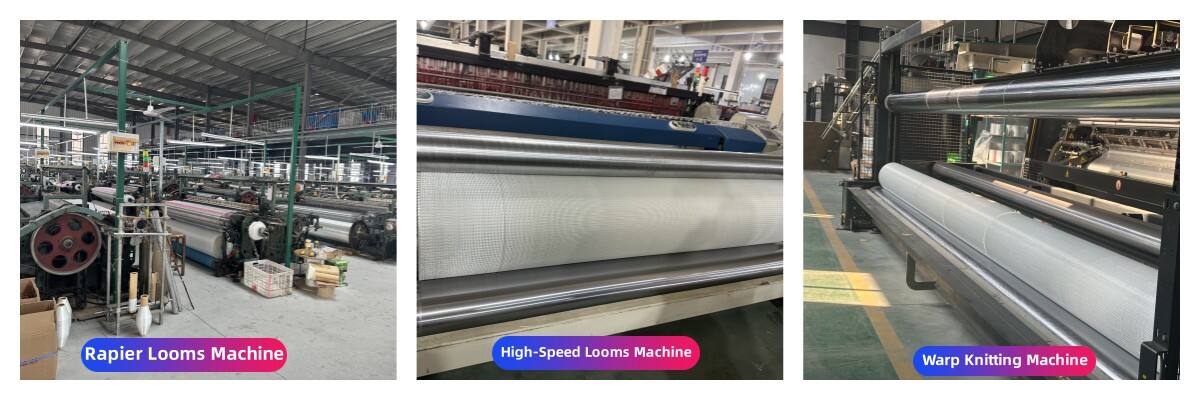

Diverse and Precision Weaving to Meet Professional Needs

We are equipped with a variety of advanced weaving equipment, including rapier looms, high-speed looms, and warp knitting machines, to meet the precise requirements of different application scenarios regarding weight, mesh size, and strength. This flexible production capability ensures that we can efficiently and accurately provide you with specification-matched, high-performance mesh fabric products.

Quality Assurance:

• Product manufacturing follows a rigorous quality control system.

• Meets relevant industry standards.

• We guarantee that the specifications of the products leaving the factory are consistent with the description and provide reliable technical support.

1. Samples

Free standard samples (you pay freight). Custom samples at cost. Shipped in 2-3 days.

2. Payment Terms

T/T: 30% deposit, 70% against B/L copy.

L/C at sight.

3. Delivery Time

15-20 days after deposit for standard products. Dedicated order tracking.

4. MOQ

1x20'GP (optimal for cost). Can start from 10,000 sqm.

5. Quality Guarantee

Standardized process. Auto & manual inspection. Full batch traceability.

6. Certificates

ISO9001, CE. Test reports available.

7. Quality Issue

24-hour response. Fast solution (replacement/compensation).

8. Our Strength

15-year manufacturer. Full supply chain control (cost & tech advantage). 5M+ sqm monthly capacity.

9. Customization & OEM

Supported. Provide details for solution.

10. Factory Visit & Partnership

Warmly welcome. Discuss annual/agency agreements for best support.

Copyright © 2025 by Shandong Rondy Composite Materials Co., Ltd. — Privacy Policy