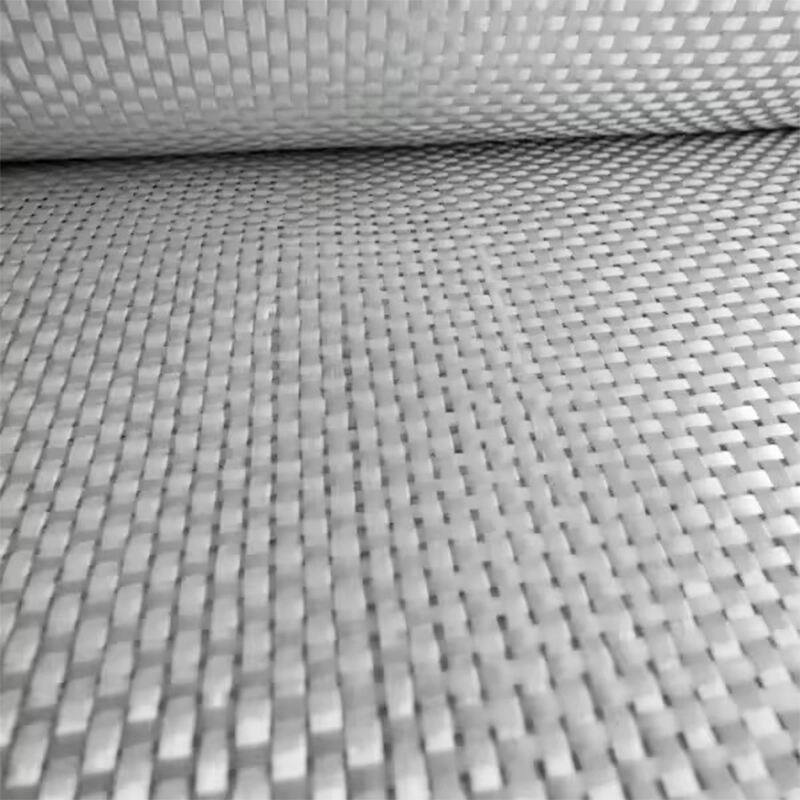

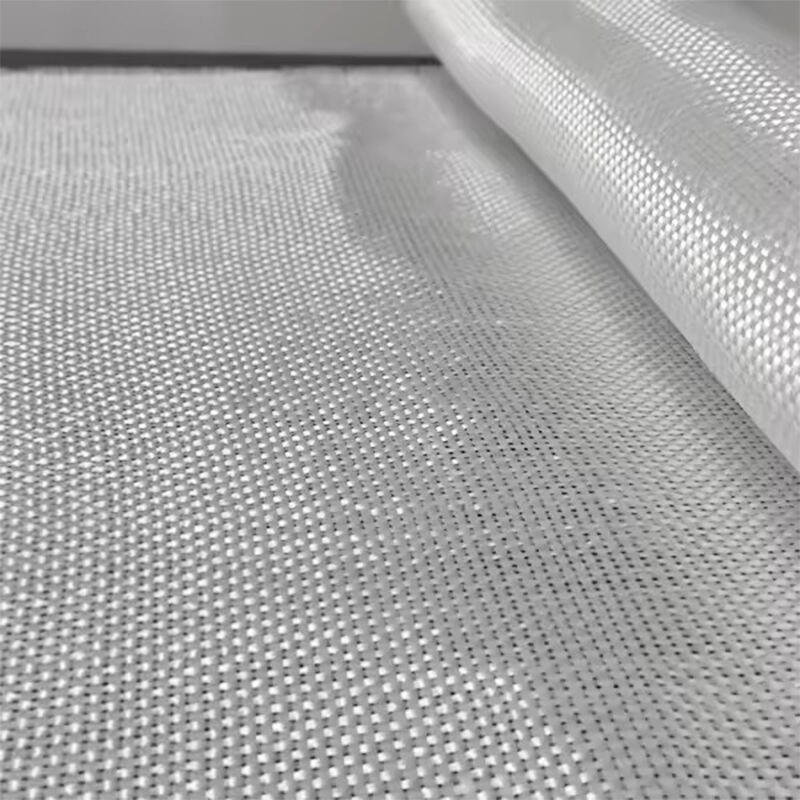

Shandong Rondy Composite Materials Co., Ltd. stands as a distinguished woven roving supplier in the global composite materials market. Our woven rovings are crafted from premium-quality glass fibers, meticulously woven into robust fabrics that exhibit exceptional strength and durability. These materials are pivotal in enhancing the structural integrity of composite products, making them ideal for a wide range of applications, including boat building, automotive components, and construction projects. As a dedicated supplier, we understand the critical role that woven rovings play in the composite manufacturing process. Therefore, we ensure that our products meet stringent quality standards, adhering to international certifications such as ISO9001 and ISO14004, as well as compliance with CE and other relevant industry norms. Our woven rovings are available in various weights and weaves, allowing for customization to meet specific customer requirements. Whether you are looking for standard or specialized woven rovings, we offer a comprehensive range of options to suit your needs. With our commitment to continuous improvement and innovation, we are constantly exploring new ways to enhance the performance and versatility of our woven rovings. Our robust support system for large-scale orders ensures that we can meet the demands of even the most extensive projects, providing timely delivery and exceptional customer service. As a woven roving supplier, we take pride in our ability to deliver high-quality products that contribute to the success of our clients' composite manufacturing endeavors.

Copyright © 2025 by Shandong Rondy Composite Materials Co., Ltd. — Privacy Policy