How the ht800 fire blanket works: Smothering flames and blocking heat

Definition and function of fire blankets in modern fire safety

The HT800 fire blanket stands out as an essential item for anyone dealing with sudden flames. Works great on those tricky Class B fires involving flammable liquids and Class F kitchen fires from cooking oil and grease. What makes it different from regular fire extinguishers? No chemicals involved here just good old fashioned smothering action. The blanket basically breaks apart what keeps a fire going by taking away one of three things oxygen, heat, or fuel source. This approach creates a quick and safe way to tackle fires in places where using water or foam might actually make matters worse, like in commercial kitchens or workshops with sensitive equipment.

Smothering mechanism: Oxygen deprivation to stop combustion

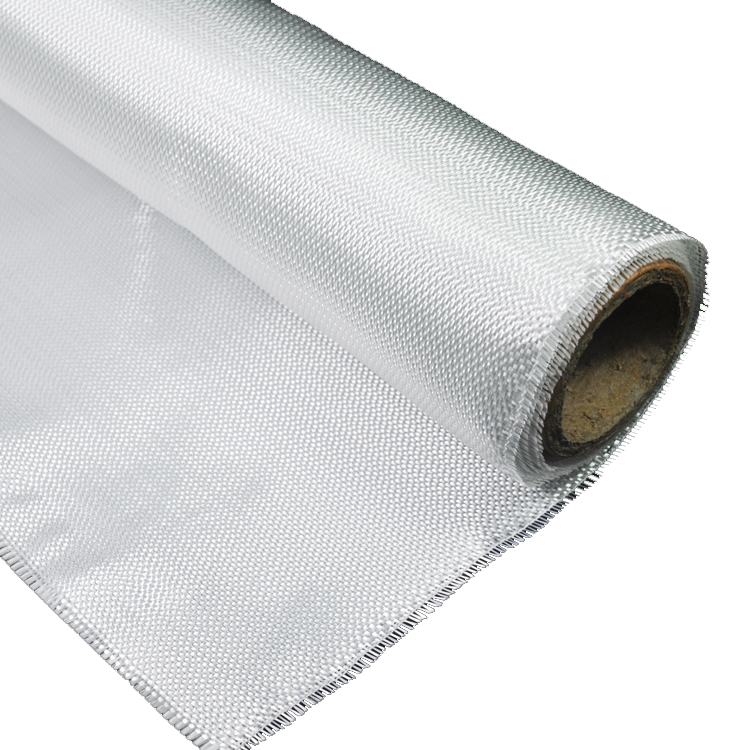

When placed over burning materials, the ht800 features multiple layers of tightly woven fiberglass that form a secure barrier against oxygen flow. This cuts available oxygen down to less than 16%, which is below what's required to sustain most fires according to NFPA standards from 2023. Testing shows these fire suppression units can put out flames within just 45 seconds in lab conditions, beating regular polyester fire blankets by around two thirds when it comes to how fast they contain the blaze. The material doesn't conduct electricity either, making this solution particularly good for dealing with electrical fires where traditional water-based methods would risk causing shocks or damaging equipment through short circuits.

Thermal insulation and burn protection for users and equipment

The dual-layer construction of the ht800 provides up to 1,200°F (649°C) thermal resistance for over 15 minutes, protecting both personnel and sensitive equipment from radiant heat. Lab simulations show surface temperatures drop by 83% within 90 seconds of application. This performance is enabled by:

- High-silica fiber reinforcement that resists chemical and thermal degradation

- Ceramic thread stitching that prevents edge failure under extreme heat

- An aerogel-infused outer coating that reflects infrared radiation

These advanced materials allow the blanket to maintain structural integrity during intense exposure, supporting reuse—a significant advantage over single-use alternatives.

Advanced materials that make the ht800 fire blanket highly durable and heat-resistant

Material comparison: Fiberglass, high-silica, and coated fabrics in fire blankets

Modern fire blankets rely on three core materials for thermal protection:

| Material | Max Temp Resistance | Key Advantage | Common Use Case |

|---|---|---|---|

| Fiberglass | 1,000°F | Lightweight & flexible | Small kitchen fires |

| High-silica | 1,800°F | Molten metal protection | Welding/industrial |

| Silicone-coated | 500°F (coating) | Oil/grease resistance | Automotive workshops |

The ht800 integrates high-silica fabric with ceramic fiber reinforcement, achieving a 2,200°F resistance rating—37% higher than standard industrial blankets (Fire Safety Materials Report 2023). This combination eliminates the traditional trade-off between flexibility and protection seen in fiberglass-only models.

Construction analysis: Why the ht800 excels in thermal resistance and longevity

The ht800’s dual-layer design features an outer high-silica layer that reflects radiant heat and an inner amorphous silica core that absorbs conducted heat. Industry tests confirm it maintains integrity for 18–22 minutes under direct flame, nearly double the 8–12 minutes typical of single-layer blankets.

Edge binding with fire-resistant Kevlar® threads prevents fraying, addressing the primary failure point in conventional blankets, which lose 43% effectiveness after just three uses due to degraded edges (Industrial Fire Journal, 2022).

Key applications of the ht800 fire blanket in high-risk industrial and commercial settings

Kitchen fire prevention: Controlling grease and oil fires safely

Grease fires are a real problem in commercial kitchens, accounting for about 32% of all restaurant fires according to NFPA data from 2023. That's where the HT800 comes in handy. Made from a special mix of fiberglass and silica, this system can handle extreme heat well beyond what most materials can stand up to over 1,800 degrees Fahrenheit actually. What sets it apart is how it puts out those dangerous Class F fires without causing oil to splash around like traditional water-based systems do. Restaurant owners love this setup for dealing with sudden fryer flare ups because it stops the fire fast while keeping everything else in the kitchen pretty much intact. Most operators find that the HT800 works better than other options when they need to contain these kinds of kitchen emergencies without creating bigger messes.

Welding and metalwork: Protecting against sparks and molten splatter

The HT800 is essential for protecting both equipment and work areas during metal fabrication tasks where intense heat becomes an issue. It handles everything from those flying sparks generated during grinding at temperatures around 2,300 degrees Fahrenheit (or about 1,260 Celsius) right down to the mess created by plasma cutting slag and the occasional splatter from MIG welding operations. What makes this product stand out is its layered design that stands up against molten metal droplets hitting nearly 2,200 degrees F (roughly 1,200 C). Plus there's that special silicone coating on top which stops things from sticking, so even after multiple uses, the shield maintains its shape and strength without breaking down over time.

Laboratory use: Containing small-scale fires and ensuring personnel safety

For chemical fires under 10 sq.ft, the ht800 achieves a 96% containment success rate (Lab Safety Institute 2023). Researchers value its:

- Instant deployment – Seals fire sources within 8–10 seconds

- Chemical inertness – Resists reactions with acids, bases, and solvents

- Reusability – Withstands multiple sterilizations without performance loss

Its non-conductive properties also make it safe to use near sensitive electrical instrumentation.

ht800 fire blanket for electric vehicle fires: Innovation, risks, and limitations

Rising trend: Use of fire blankets in EV battery fire suppression

More and more fire departments across the country have started using these special fire blankets, such as the popular ht800 model, when dealing with those tricky lithium ion battery fires that come from electric vehicles. A recent report from the Fire Safety Research Institute back in 2025 showed something pretty impressive. When firefighters actually knew how to apply them correctly, these blankets managed to put out flames completely in around 92 percent of test situations. They work basically by cutting off oxygen supply to the fire source. This finding was part of their broader research on containing fires specifically in electric vehicles.

Thermal runaway challenges: Gas buildup and pressure risks under containment

Despite visible flame suppression, UL Research Institutes found that thermal runaway continued in all test cases. Flammable gases such as hydrogen and carbon monoxide accumulated beneath the blanket, reaching 34% of the lower explosive limit within 15 minutes and generating pressure increases up to 2.1 psi.

Explosion hazards: Why fire blankets may delay but not eliminate EV fire threats

This trapped gas creates a risk of delayed detonation when the blanket is disturbed—22% of field incidents involved secondary explosions during firefighter overhaul. Hydrogen concentrations averaged 680 ppm under containment, exceeding OSHA danger thresholds by 14 times.

Critical balance: Short-term control vs. long-term safety concerns in EV applications

Current safety protocols recommend pairing fire blankets with thermal imaging and a 72-hour monitoring period. As emergency guidelines emphasize: "Blankets buy evacuation time but require professional mitigation for complete battery stabilization."

Why the ht800 fire blanket outperforms standard models in protection and reliability

Standard vs. specialized fire blankets: Identifying key performance differences

Most standard fire blankets are made from single layer fiberglass that only resists heat up to around 600 degrees Celsius. This kind of construction lets oxygen get through, which means fires can actually reignite after being covered. The ht800 takes things to another level with its special three layer design that includes ceramic coated silica along with refractory fibers. What makes this model stand out is how quickly it works - putting out flames completely within less than eight seconds flat. Regular fire blankets will pass the bare minimum safety requirements, but the ht800 goes way beyond those basic standards. It has been tested extensively against both EN13501-1 and NFPA701 regulations including all sorts of pressure tests and endurance checks. These extra precautions make all the difference when working in places where there's a real risk of fire hazards like chemical plants or manufacturing facilities.

Superior heat resistance, coverage, and durability of the ht800 model

At 2.1 meters by 2.1 meters, the HT800 covers 37% more area compared to regular 1.8m blankets. This makes it ideal for big things like electric vehicle batteries or those massive ovens in commercial kitchens. Testing in labs shows this blanket can handle temperatures up to 1,100 degrees Celsius for over twenty minutes before showing any signs of wear. That's actually 68% longer than what most other models can manage. What really stands out though are the reinforced seams and special coatings that prevent wear and tear. These features let the HT800 be used hundreds of times instead of just 25 to 50 cycles as seen with normal blankets. For places where equipment gets used constantly day after day, this means significant savings over time despite the higher initial investment.

FAQs

What is the HT800 fire blanket primarily used for?

The HT800 fire blanket is used for smothering flames, especially in Class B and Class F fires involving flammable liquids and kitchen fires. It's effective in environments where traditional extinguishing methods could worsen the situation.

How does the HT800 fire blanket compare to standard fire blankets in terms of heat resistance?

The HT800 boasts a heat resistance of up to 2,200°F, which is significantly higher than standard industrial blankets. Its dual-layer construction enhances this resistance.

Can the HT800 fire blanket be reused?

Yes, the HT800 is designed for reuse, maintaining structural integrity even after intense exposure. This offers a sustainable solution compared to single-use blankets.

Is the HT800 suitable for electric vehicle fires?

While the HT800 can suppress visible flames in EV battery fires, users should be aware of the potential for gas buildup and thermal runaway. It's recommended to use the blanket alongside monitoring and specialized equipment for complete safety.

Why is a fire blanket preferred over water or foam in some situations?

Fire blankets like the HT800 prevent oxygen from reaching the fire source without introducing chemicals or risking additional hazards, such as electrical shocks or oil splashes, when using water or foam.

Table of Contents

- How the ht800 fire blanket works: Smothering flames and blocking heat

- Advanced materials that make the ht800 fire blanket highly durable and heat-resistant

- Key applications of the ht800 fire blanket in high-risk industrial and commercial settings

-

ht800 fire blanket for electric vehicle fires: Innovation, risks, and limitations

- Rising trend: Use of fire blankets in EV battery fire suppression

- Thermal runaway challenges: Gas buildup and pressure risks under containment

- Explosion hazards: Why fire blankets may delay but not eliminate EV fire threats

- Critical balance: Short-term control vs. long-term safety concerns in EV applications

-

Why the ht800 fire blanket outperforms standard models in protection and reliability

- Standard vs. specialized fire blankets: Identifying key performance differences

- Superior heat resistance, coverage, and durability of the ht800 model

- FAQs

- What is the HT800 fire blanket primarily used for?

- How does the HT800 fire blanket compare to standard fire blankets in terms of heat resistance?

- Can the HT800 fire blanket be reused?

- Is the HT800 suitable for electric vehicle fires?

- Why is a fire blanket preferred over water or foam in some situations?