PE ve PVC Çadır Bezleri Arasındaki Temel Farklar

Malzeme Bileşimi ve Yapısı

PE ve PVC örtüler yapıları bakımından oldukça farklıdır ve bu durum ağırlıklarını ve kullanım kolaylıklarını etkiler. PE örtüler yüksek yoğunluklu polietilenden üretilir ve genellikle hem hafif hem de maliyet açısından daha uygun olurlar. Bu özellikler, PE örtüleri taşıma işlerinde ve sınırlı alanlarda depolama için ideal kılar. Öte yandan PVC örtüler, polivinil klorür kullanılarak üretilir ve daha kalın, sağlam bir yapı sunarlar. Bu dayanıklı örtüler, zorlu hava koşullarına karşı daha iyi direnç gösterir ve bu yüzden inşaat sahalarında ve depolarda ciddi işler için tercih edilirler. Bu iki seçenek arasında karar verirken dokuma deseni ve kalınlığa dikkat etmek oldukça önemlidir çünkü bu faktörler, örtünün baskı altında ne kadar dayanıklı olacağını belirler. Sektörde dolaşan bazı istatistiklere göre PVC, kopmadan önce PE'ye göre daha fazla esneme dayanıklılığı gösterir. Bu nedenle makinaları kaplamak veya dış mekân da geçici barınaklar kurmak isteyen çoğu kişi PVC örtüleri tercih eder.

İçsel Özellikler ve Performans Kapasiteleri

PE ve PVC örtüler, çeşitli durumlarda nasıl performans göstereceklerini etkileyen farklı özelliklere sahiptir. Polietilen örtüler genellikle oldukça esnek ve yırtılmaya karşı dirençli olup geçici işler ve kısa vadeli kurulumlar için uygundur. Zorlanmaya karşı kolayca yırtılmazlar, bu yüzden bir süre malzemeleri veya inşaat alanlarını kapatmak için iyi çalışırlar. PVC örtüler söz konusu olduğunda, bunlar PE ürünlerine göre suya ve UV ışığına karşı daha iyi direnç göstermeleriyle öne çıkarlar. Bu nedenle, uzun süre yağmur ve güneş ışığına maruz kalacakları dış mekanlarda sıklıkla kullanılırlar. Üreticiler PVC örtülere küf oluşumuna ve statik elektrik birikimine karşı ekstra koruma sağlayan özel kimyasallar eklerler. Yapılan araştırmalar, PVC'nin genellikle sert hava koşullarında PE'ye göre daha iyi performans gösterdiğini, çünkü daha uzun ömürlü olduğunu ve daha güçlü olduğunu göstermektedir. Malzemelerin zaman içinde sürekli korunmasını gerektiren durumlarda PVC, başlangıçta biraz daha pahalı olsa da daha iyi bir seçenek olmaya devam eder.

Dayanıklılık ve Ömür Faktörleri

Örtülerin ne kadar dayanacağı tamamen nasıl yapıldıklarına ve kumaşın hangi tür işlemlerden geçirildiğine bağlıdır. PE örtüler genellikle daha hafif malzemelerden üretilir, kalın ya da ağır iş tipi değildirler. Bu tür örtüler, bir şeyin taşınması sırasında ya da açık alanda geçici olarak kapatılması gerektiğinde harika sonuç verir. Çoğu kişi, üç yıl kadar iyi şekilde kullanıldıklarını ve bu süre sonra değiştirilmelerinin gerektiği görüşünde; bu da esnekliğin sonsuza kadar dayanmadan daha önemli olduğu durumlar için oldukça yeterlidir. Diğer taraftan, PVC örtüler daha kalın ve dayanıklı malzemelerle üretilmiş oldukları için çok daha sağlamdırlar. Bazıları on beş yıla kadar dayanabilir! Bu tür ömür uzunluğu, yağmur, kar, güneşe bağlı bozulmalar ya da doğanın sunduğu diğer zorlayıcı koşullara maruz kalan ciddi uygulamalar için onları ideal hale getirir. Ekstra kalın kaplama sayesinde aşınma ve yıpranmaya karşı koruma sağlar, bu yüzden yıllarca kötü muameleye rağmen iyi şekilde görevlerini sürdürürler.

Çevresel Direnç (UV/Kimyasallar/Hava Koşulları)

PE ve PVC örtüler arasında karar verirken doğaya karşı dayanıklılıkları çok önemli olur. PE, güneşe maruz kaldığında iyi bir UV direnci gösterdiği için dış mekan kullanımları için tercih edilir; bahçe örtüleri ya da açık hava depolama gibi alanlarda sıklıkla bu tür ürünler tercih edilir. Ancak kimyasal dirençten söz ediyorsak PVC öne çıkar. İnşaat sahaları ve agresif maddelerle çalışan fabrikalar, bu malzemelerin sert kimyasallara karşı kolayca bozulmadığını bildikleri için PVC'ye güvenirler. PVC'yi daha da farklı kılan, sadece UV ışığına değil aynı zamanda pek çok olumsuz etkene karşı da dirençli olmasıdır; örneğin uzun süre su altında kalma, yüzeylerde küflenme ve doğanın sunduğu diğer zorlayıcı koşullar. Bu yüzden özellikle örtülerin kötü hava koşullarında yırtılacağı ya da endüstriyel kimyasallara maruz kalacağı işlerde birçok müteahhit PVC tercih eder. Gerçek dünya kullanımının birkaç ayı geçmesiyle dayanıklılık farkı daha da belirgin hale gelir; beklenmedik fırtınalar ya da kimyasal sızıntılar karşısında bu fark daha çok hissedilir.

Maliyet Etkinlik vs Uzun Vadeli Değer

Maliyet ile uzun vadeli değer karşılaştırıldığında, PE ve PVC örtülerin her birinin kendine özgü avantajları vardır. PE kesinlikle daha düşük başlangıç maliyetine sahip olduğu için geçici işlerde veya bütçenin kısıtlı olduğu durumlarda daha iyi bir seçim olabilir. Ancak PVC, uzun vadede kendini amortise edecek olan daha yüksek bir fiyat etiketine sahiptir. Bu malzemeler çok daha uzun ömürlüdür ve dayanıklılıkları daha fazladır; bu da yenileme ihtiyacını azaltır. Özellikle üretim hatlarını durduran bir arızanın verimliliği ciddi şekilde etkileyebileceği fabrikalarda ya da depolarda bu durum oldukça önemlidir. Elbette PVC satın alımı başlangıçta daha pahalı olsa da, çoğu işletme, düşük kaliteli malzemelerle yaşanan sürekli yenileme ve tamirat maliyetlerini düşününce genel olarak daha ekonomik olduğunu görür.

Proje-Özgü Uygulamalar Rehberliği

PE Örtülerin İdeal Kullanım Alanları

Polietilen örtüler kamp gezileri gibi geçici işlerde, ev taşırken mobilyaları korumada ya da hızlıca geçici barınaklar kurmada harika iş görür. Hafifliği ve kullanımı kolay olması, özellikle taşınabilir bir şeye ihtiyaç duyulduğunda çok önemlidir. Yürüyüş sırasında beklenmedik yağmurun yakalaması ya da bahçe sandalyelerini kötü hava koşullarından korumak istenmesi gibi durumları düşünün. Bu plastik örtüler oldukça hızlı açılabilir ve sabitlenebilir. Dış mekânlarda zaman geçiren bazı insanlar arasında yapılan bir ankette, çoğu insanın hızlı çözümler için PE örtüleri diğer alternatiflerden daha iyi oldukları için tercih ettikleri ortaya çıkmıştır. Kimi şeyleri hızlıca kapatmak gerektiğinde ama uzun süre kalmayacaksa, pek çok kişinin garajlarında ya da kamyonlarında birkaç tane bu örtüleri hazır bulundurmasının bir nedeni yok değil.

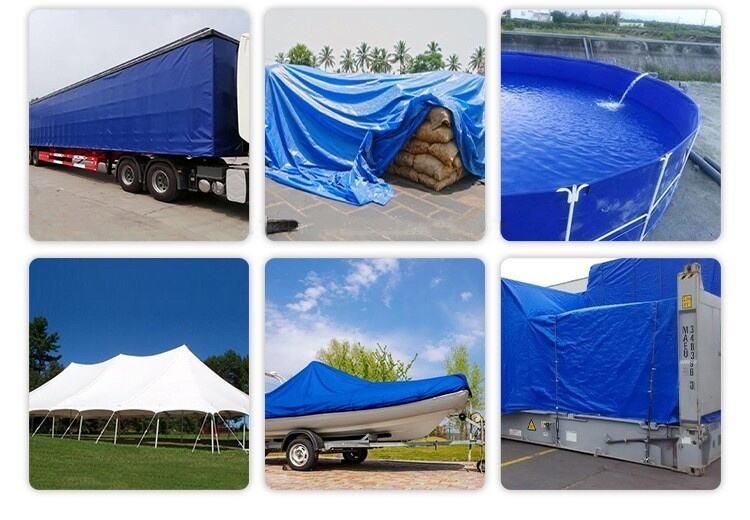

PVC Brandalar İçin En Uygun Senaryolar

PVC örtüler, endüstriyel çalışmalarda, tarım işlerinde ve haftalarca ya da aylarca süren büyük açık hava etkinliklerinde tercih edildiğinde gerçekten öne çıkar. Bu örtüler dayanıklı yapılarıyla üretilir ve doğanın onlara sunduğu her şeye dayanacak şekilde dizayn edilmiştir. Bu yüzden inşaat alanlarında ve araç depolama bölgelerinde oldukça yaygındırlar. Yükleniciler, yağmurdan, tozden ve güneşe bağlı hasarlardan korumak için pahalı ekipmanların üzerine bu ağır iş örtülerini sererler. Festival veya spor etkinliklerinde ise organizatörler, PVC örtülerin daha ucuz alternatiflerin aksine kolayca yırtılmaması sebebiyle onlara güvenerek kullanırlar. Alan çalışanları, hafif malzemelerin tamamen başarısız olacağı fırtınalar veya aşırı sıcaklar sırasında bu örtülerin nasıl dayandığına dair hikayeler anlatırlar. Bu tür dayanıklılık, işletmelerin diğer kumaş alternatiflerine göre sürekli değişim ihtiyacını ortadan kaldırarak uzun vadede para tasarrufu sağlamasını sağlar.

Özel Gereksinim Hususları

İnşaat ve endüstriyel projelerin bazıları, ateş direnci veya örtüler için ek güvenlik özellikleri gibi konularda ekstra dikkat gerektirir. Güvenlik kurallarına uymak, isteğe bağlı değil, zorunlu olduğu iş ortamlarında bu özellikle önem kazanır. Örneğin yangına dayanıklı örtüler, kıvılcımların veya alevlerin çıkması muhtemel yerlerde herkesin güvenliğini sağlamak ve potansiyel riskleri azaltmak için hayati derecede önemlidir. Çoğu yapı yönetmeliği, farklı durumlarda hangi tür malzemelerin kullanılması gerektiğini belirterek denetimlerden geçmelerini ve yasal sınırlar içinde kalmalarını sağlar. Uzun süredir sektörede olan uzmanlar, bu tür faktörlere göre doğru örtü tipinin seçilmesinin, sıkı güvenlik yönetmeliklerine tabi işlerde fark yarattığının farkındadır.

Seçim Rehberi: Gereksinimleri Malzemeyle Eşleştirme

Bütçe ve Süre Faktörleri

PE ve PVC örtüler arasında karar verirken bütçe hususları ve bir projenin ne kadar süreceği gerçekten önemlidir. Polietilen örtüler, genellikle dar bütçelerle veya kısa vadeli işlerle çalışan kişiler için en yaygın seçenek olmaktadır. İnşaat alanlarını yağmurlu hava nedeniyle ertelenen çalışmalarda veya gece boyu ekipmanları korumak amacıyla örtülerin çoğu yüklenici tarafından satın alındığında, fiyat açısından oldukça uygunlardır. Bu tür geçici çözümler için yüksek harcama yapmak mantıksız olacağından, fiyat performansı bu durumlarda oldukça uygundur. PVC örtüler başlangıçta daha yüksek bir fiyat etiketine sahiptir ancak genellikle çok daha uzun ömürlüdürler. Aylar hatta yıllar süren projeler için başlangıçta yapılan ek harcama genellikle ilerleyen zamanlarda kendini amortismana uğratır. Daha ucuz alternatifler nedeniyle PVC örtülere yönelmeyen yükleniciler genellikle yıpranan örtüleri defalarca değiştirme zorunda kalırlar ve bu maliyetler beklenenden çok daha hızlı artar. Yeni örtü satın alımlarında sürekli harcama yapılması gereğini ortadan kaldırarak elde edilen tasarruf, birçok durumda başlangıçtaki yüksek maliyeti oldukça hızlı bir şekilde dengeleyebilir.

Maliyet açısından, uzmanların çoğu polietilen örtülerin ilk bakışta daha ucuz görünmesine rağmen, zamanla dayanıklılık gerçekten önemli hale geldiğinde daha çabuk yıprandığını belirtiyorlar. Gerçek sektör verilerine baktığımızda da ilginç bir tablo çıkıyor ortaya: evet, PE örtüler başlangıçta çok daha düşük maliyetli oluyor ama PVC'li alternatifler uzun vadede bakım giderlerinde yaklaşık %30 tasarruf sağlıyor. Özellikle birkaç mevsim boyunca ya da zorlu hava koşullarında dayanabilecek örtü çözümlerine ihtiyaç duyanlar için bu durum oldukça mantıklı. Hemen şimdi ne kadar harcayacağı ile ileride ne kadar dayanacağı kıyaslandığında, çoğu profesyonel genellikle en düşük fiyatlı seçeneğe değil, zaman içinde daha iyi değer sunan malzemelere yöneliyor.

Çevresel ve Yük Gereksinimleri

Çadır bezi malzemesi seçerken ortamın türü ve ne kadar ağırlığın desteklenmesi gerektiği büyük ölçüde önemlidir. Hava durumu çok değişken olduğunda dayanıklı işler için PVC çadır bezleri tercih edilmelidir çünkü bunlar zor koşullarla karşılaşılsa bile kolay kolay dayanıklılıklarını yitirmezler. Bu çadır bezleri yırtılmadan daha ağır yükleri taşıyabilirler, bu yüzden rüzgarlı hava veya kar yağışı sırasında bile yerinde kalırlar. Bu yüzden inşaat sahaları ve depolama tesisleri bunlara çokça güvenir. Diğer taraftan, polietilen (PE) çadır bezleri daha hafif işlerde veya hava koşulları çok sert olmadığında yeterli performansı gösterirler. Bunlar genellikle bahçe mobilyalarını yağmurdan korumak veya açık hava etkinlikleri için geçici siper oluşturmak amacıyla kullanılır çünkü taşınmaları kolaydır ve hafif yağmurlara ve güneşe karşı yeterli koruma sağlarlar.

Araştırmalar, PVC örtülerin PE örtülerin ağırlığının yaklaşık üç katını taşıdığını göstermektedir. Bu da onları dayanıklılığın en önemli olduğu işler için ideal hale getirir. Bununla birlikte, PE, fazla basınç veya ağır kaldırma işlemi gerektirmeyen durumlarda daha iyi sonuç verir. Bu malzemeler arasında seçim yaparken insanlar, örtülerinin günlük olarak maruz kalacağı stresin türünü düşünmelidir. Bazı durumlar dayanıklı ve uzun ömürlü seçenekler gerektirirken, diğerleri hafif yükler altında kırılmadan bükülebilen daha esnek bir ürün tercih edilebilir.

Yangın Geciktiriciliği ve Güvenlik Özellikleri

İnşaat alanları ya da büyük etkinlikler söz konusu olduğunda yangına dayanıklılık çok büyük önem taşır. Alevlere direnç gösteren malzemelerin seçilmesi yalnızca önemli değil, aynı zamanda tüm o güvenlik kuralları ve bir şeyler yanlış giderse ne olacağı düşünüldüğünde hayati derecede önemlidir. PVC örtüler, içlerinde doğdukları yapıda yangına dirençli özellikler taşıdıkları için katı güvenlik gerekliliklerinin geçerli olduğu işlerde başvurulan başlıca malzeme haline gelirler. Buna karşılık PE örtüler genellikle alevlere karşı hiç direnç gösteremezler. Bu da yangın korunumunun sadece istenilen değil, aslında ihtiyaç olduğu durumlarda ciddi sorunlara yol açabilir. Bu malzemeler arasındaki fark, yangın güvenliği standartlarına uygunluğun her şey anlamına geldiği denetimler ya da acil durumlarda özellikle belirgin hale gelir.

Yangın güvenliği uzmanları, insan topluluklarının bulunduğu ya da doğası gereği risk barındıran yerlerde çalışırken yangına dayanıklı malzemelerin kullanılmasının ne kadar önemli olduğunu sürekli vurgular. PVC'nin yangın güvenliği yönetmeliklerinin çoğunu karşıladığı ve aslında tehlikeli durumların gelişim riskini azalttığı için birçok uzman özellikle PVC önermektedir. Farklı işler için naylonlar seçilirken yangın güvenliği öncelikli düşünülmelidir. Doğru malzeme seçimi sadece kurallara uymakla kalmaz, aynı zamı acil durumlarda can kurturur. Müteahhitler bu faktörleri projeye özgü gereksinimlerle dikkatli bir şekilde değerlendirmeli ve bütçe sınırlarını göz önünde bulundurmalıdır.